The case of NEBA #StoriesofExtremeProductivity

In today’s world, high productivity is not simply an added commercial bonus, it is a requirement.

This is why NEBA, a company of the leading appliance manufacturer Libson Group, chose us.

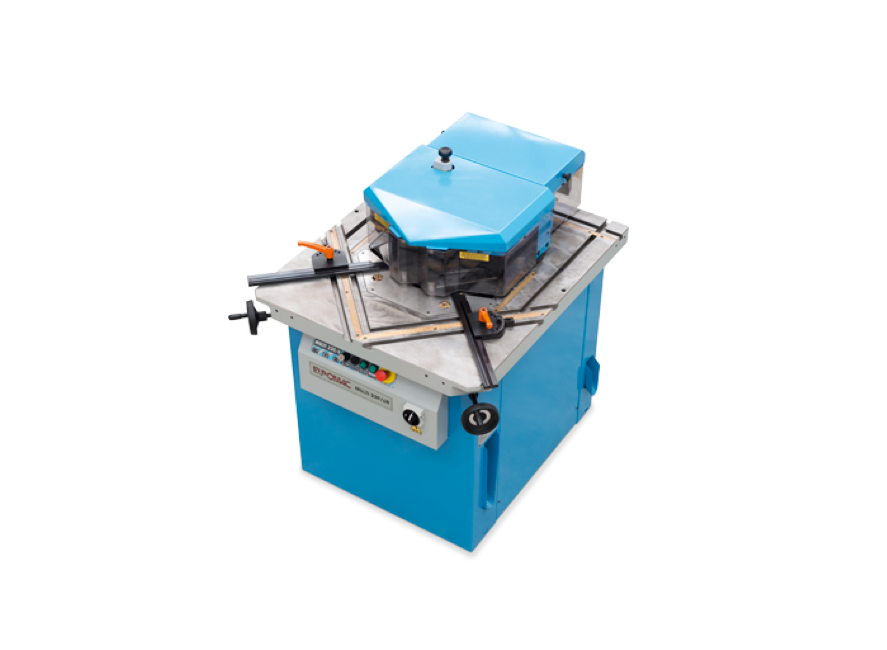

An entire automated punching, forming, marking, ribbing and bending line for the production of electric ovens for domestic use made by Euromac.

This is a project studied in partnership with the company, which described to us both its production and logistics requirements.

Indeed, the Euromac automated line provides the opportunity to configure numerous solutions, adapting to each specific need while optimising each operational phase to the maximum.

What is its objective? Its objective is to improve performance and maximise the profitability of the end product.

Technical specifications of the punching and bending line

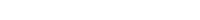

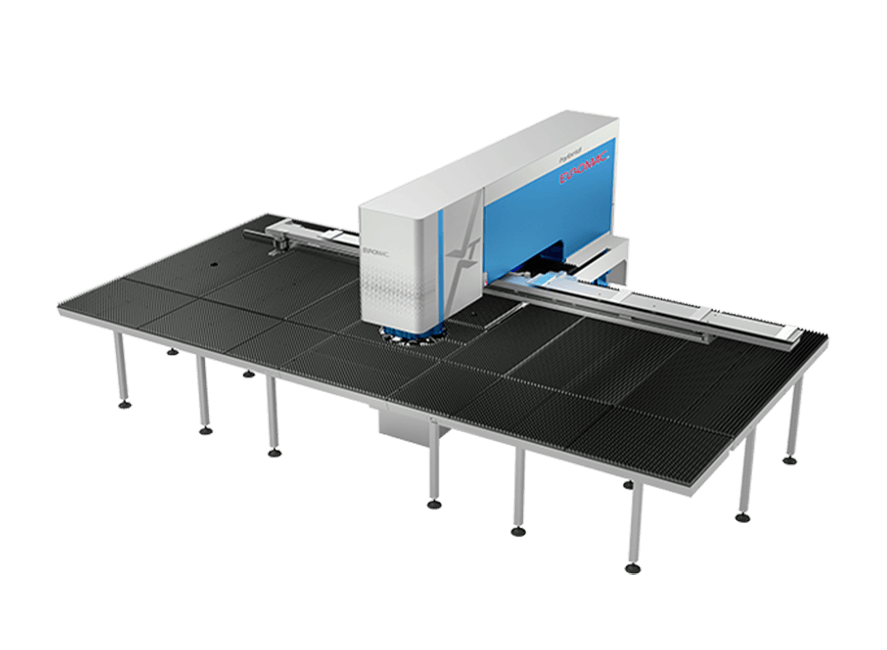

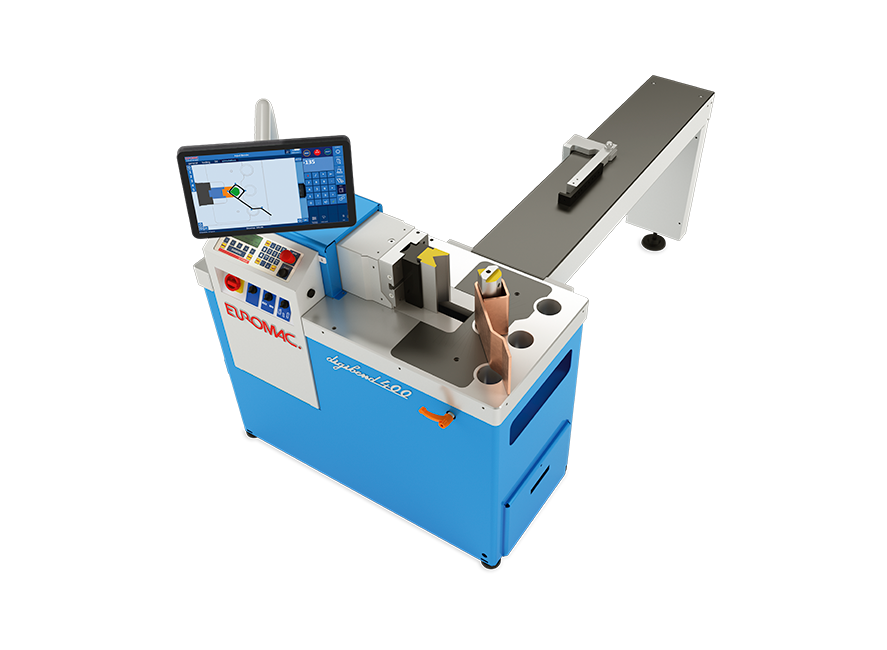

- Euromac XT punching machines with an automated loading/unloading station

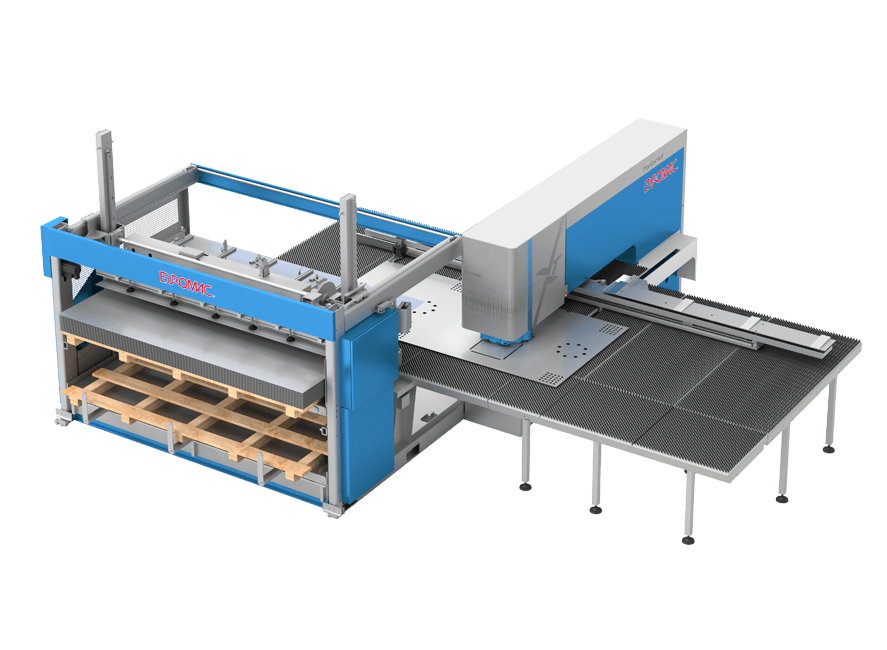

- FX Bend 2550 press brakes

- 2 Robots on rails

- Finished and stacked parts without micro-joints

- Loading area up to 3000×1500 unloading area up to 11 Euro pallets

- Unloading of workpieces onto pallets for manual bending or directly onto the centring machine or 2 loading zones for bending

- It is possible to machine directly by making either stock or kits according to the type of finish the part requires

Finding extreme productivity solutions is both our job and our passion.

Contact us to arrange a briefing. Our technical managers are at your disposal!