Robots, AI, autonomous machines. For Euromac, this is the present, not the future.

It used to be the subject of science fiction. Now, it is part of our daily work.

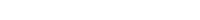

Automation in the field of sheet metal processing is reaching levels unthinkable just a few years ago.

Is your business ready?

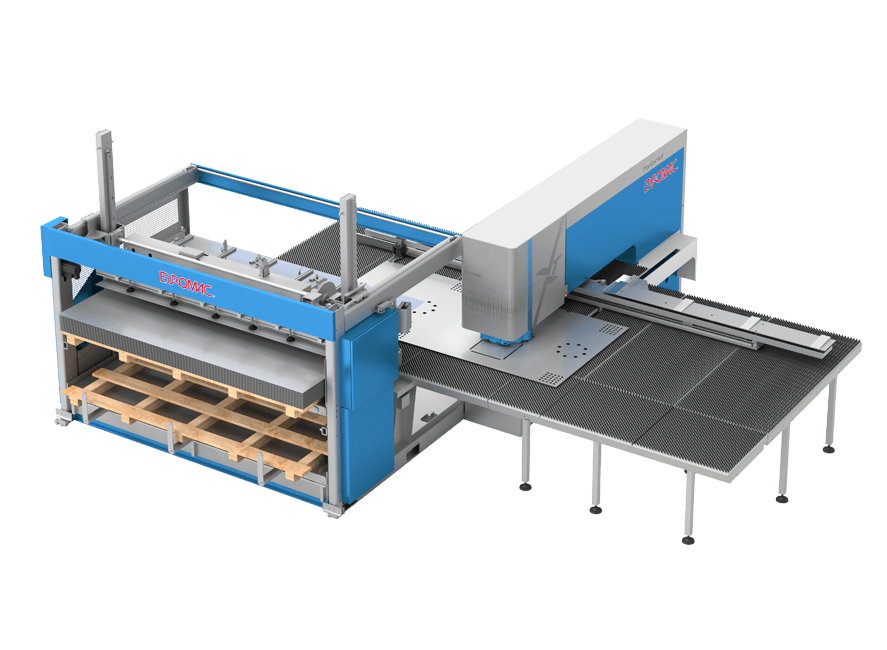

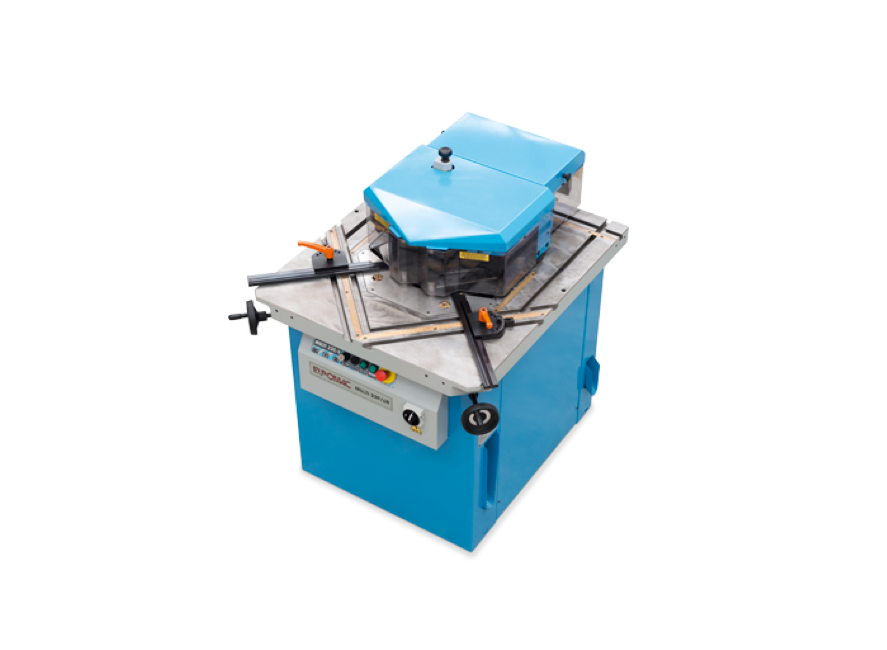

Euromac robot: the flexibility of a seamless human arm

Robotics has made great strides in recent years and we at Euromac have enthusiastically embraced this revolution!

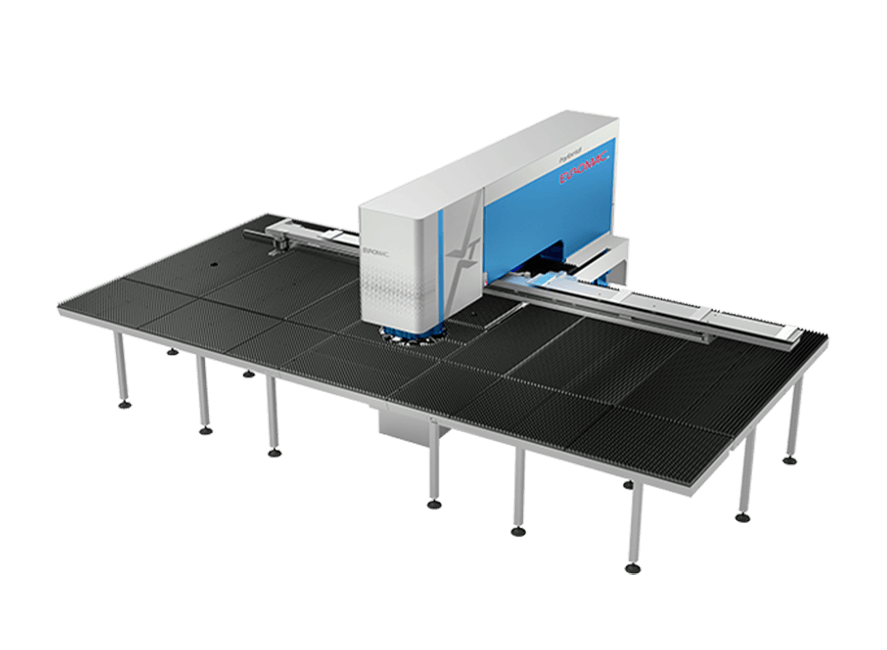

It is with increasingly advanced robotic arms like our own that we can achieve true automation: a type that is replicable, efficient and fully autonomous.

Because, with true automation, you can schedule your entire production and run your machines overnight, reducing energy and heating costs.

Because timeframes, costs and quantities of parts become precise and predictable figures.

Because if you remove the unknowns from your production line, what remains is efficiency and your margins.

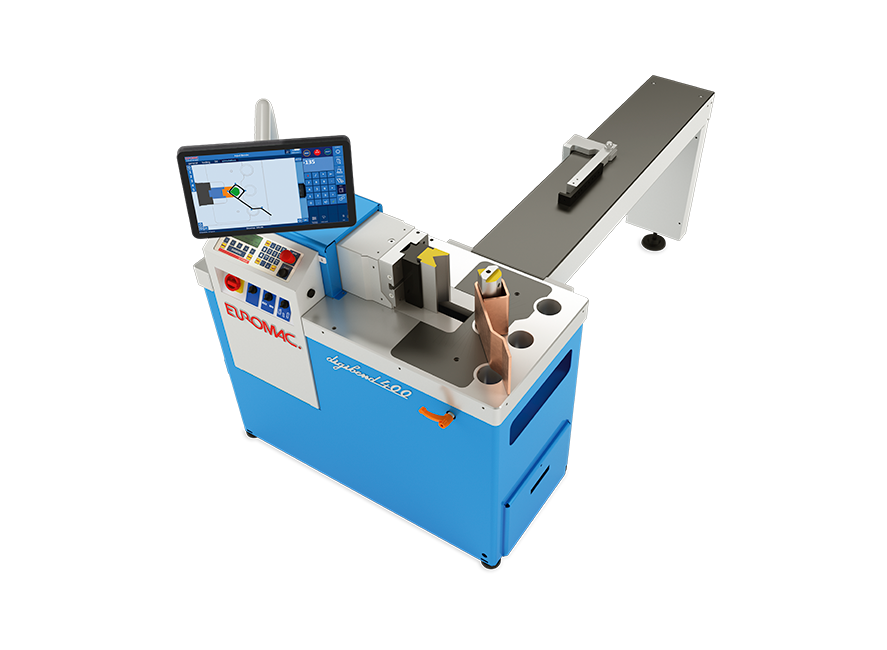

Euromac software: simulate the present, prepare the future

We are very proud of the software of our automation solutions.

With each evolution, our software has greatly improved in three respects: ease of use, optimisation of resources and simulation of production.

Thanks to its ease of use, the software can be easily mastered even by those who have only basic computer skills.

Thanks to the resource optimisation feature they make the most of each sheet of metal, greatly reducing your costs.

Thanks to the production simulator, you can test the whole process from loading the material to unloading the finished piece without moving a gram of sheet metal.

Euromac automation: not products, but solutions

Many sell products, few sell real solutions.

An automation solution must include efficient machinery, flexible robots and, of course, advanced software. But it cannot be said to be complete without precise pre-purchase advice, personalised training and prompt and helpful service.

Are you ready for real automation? Contact us!