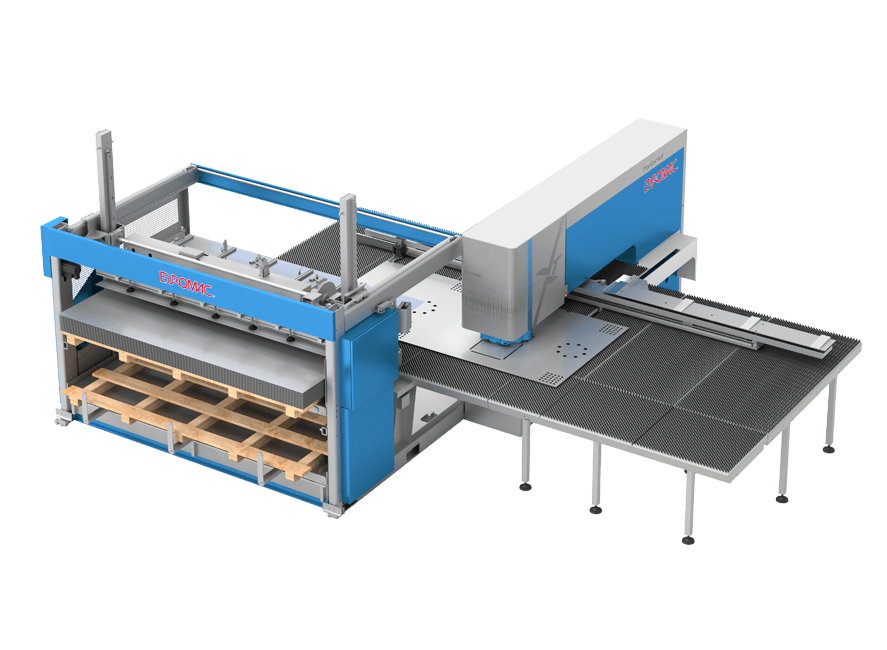

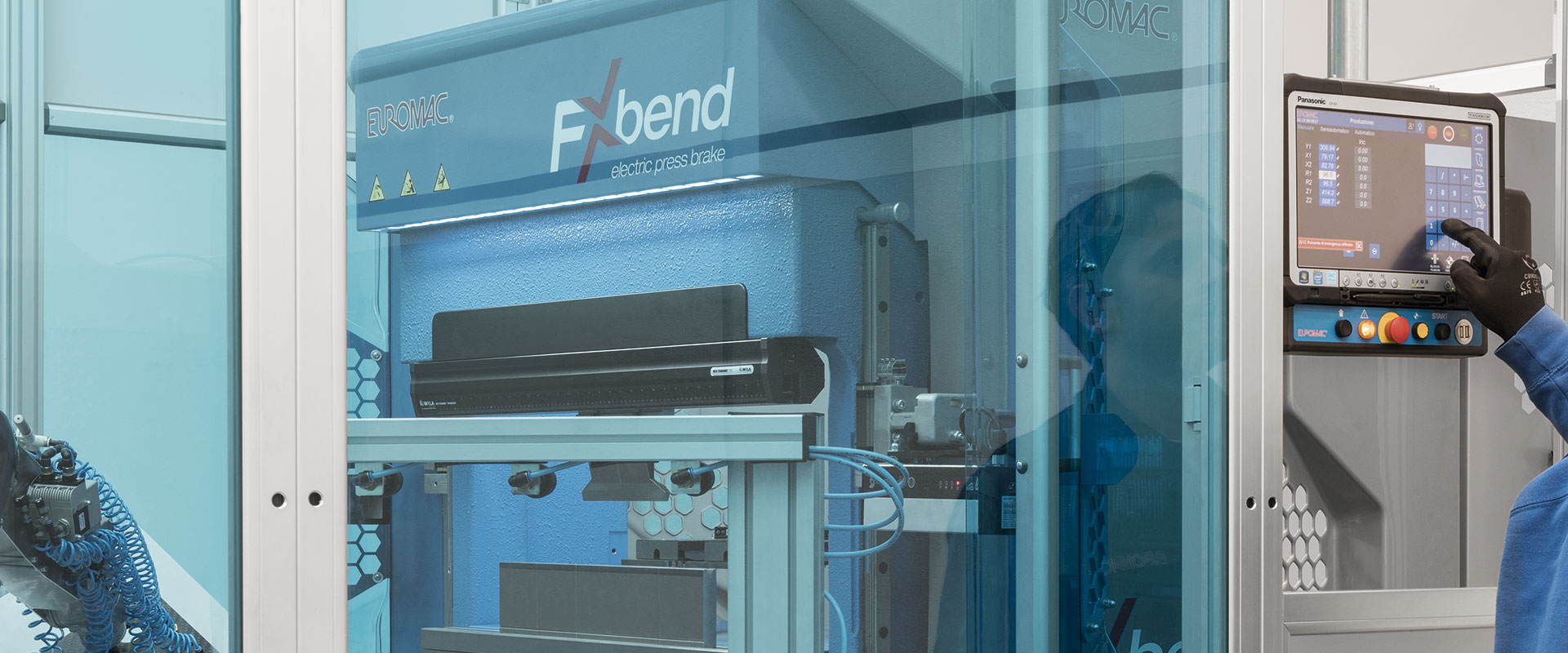

This is the modular system to configure your fully automated bending cell. Euromac provides a complete solution, designing and developing every element of the structure, from the machine to integration with the robot, right up to the software that manages the production process. Euromac automated press brake machines, the ideal solution to optimise the quality of bending operations and production times.

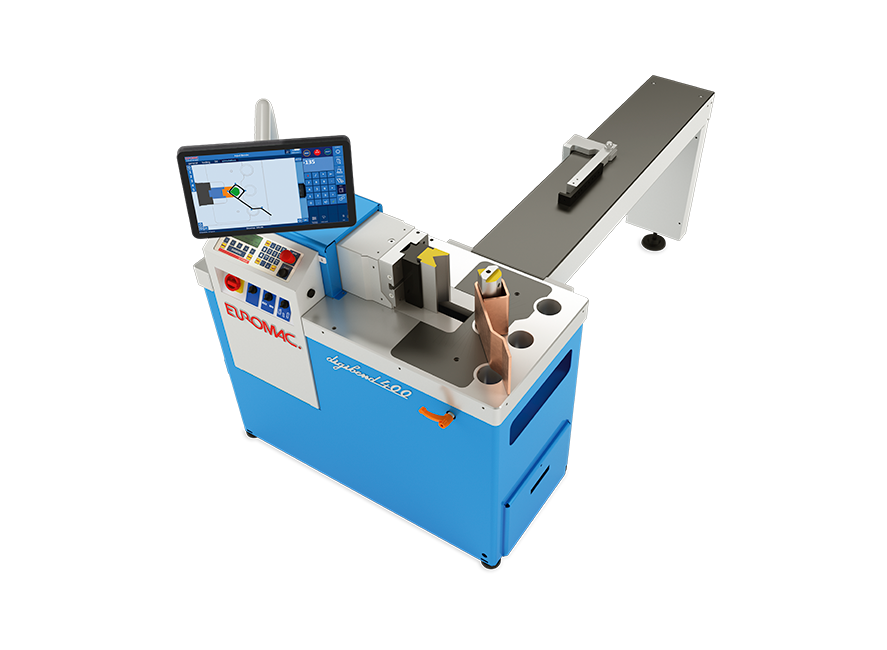

Off-line office programming, easyand intuitive.

Plan your work production regardless of the number of pieces. With our cell it will be easy and fast to launch any production avoiding the teaching phase.

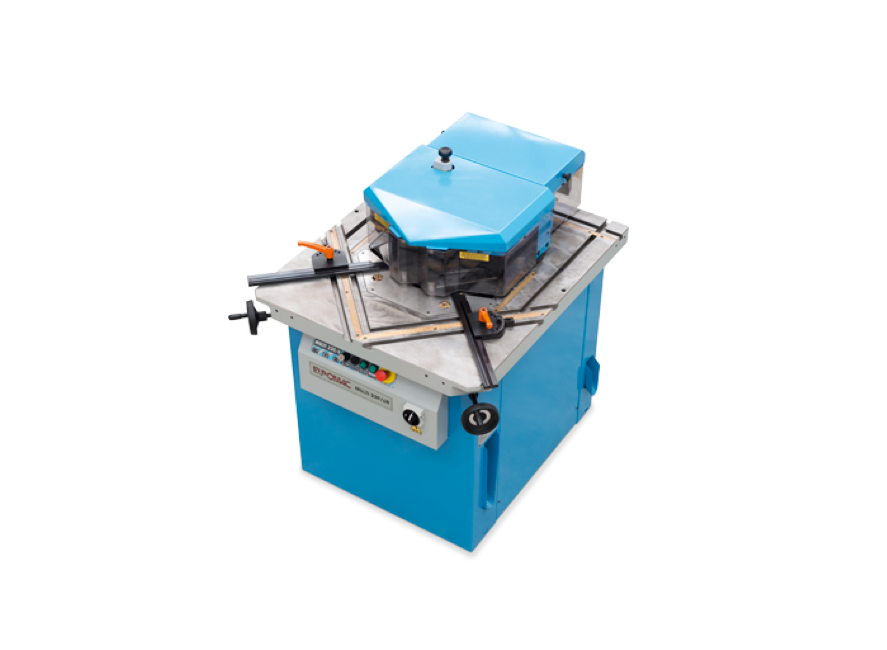

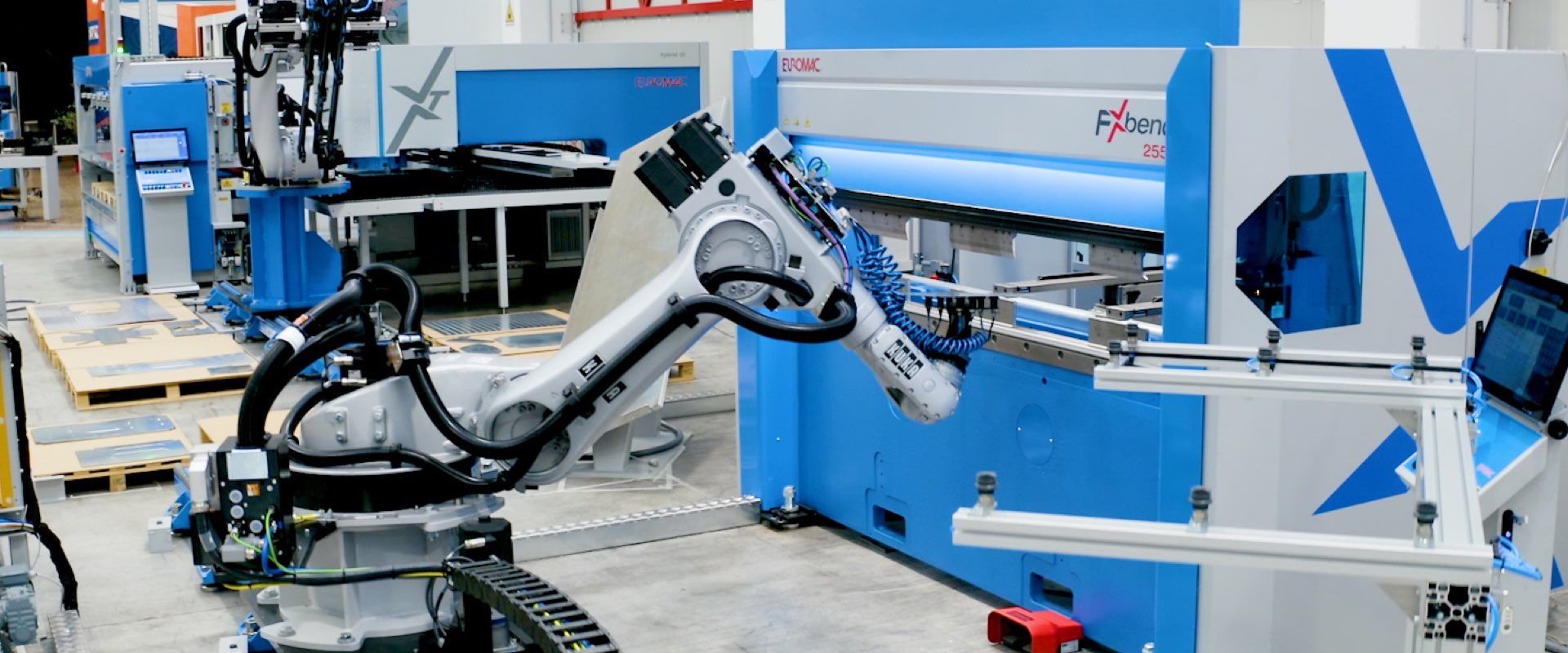

Integrated structure between machine and robot.

The system originates as unique element, with integrated robot

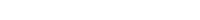

as part of the structure of FX bend itself. An automated compact

production cell is optimised with a small foot print.

System completely realized by Euromac.

Euromac provides a complete solution, designing and

developing every single element of the structure, from the

machine and the robot integration, to the software that runs the

production. A complete, reliable and friendly-use system.

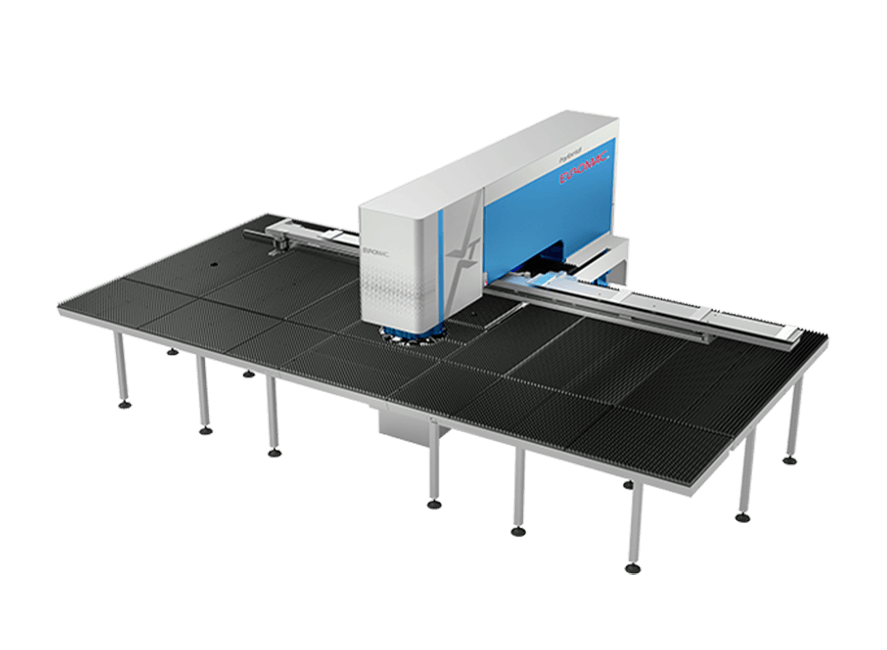

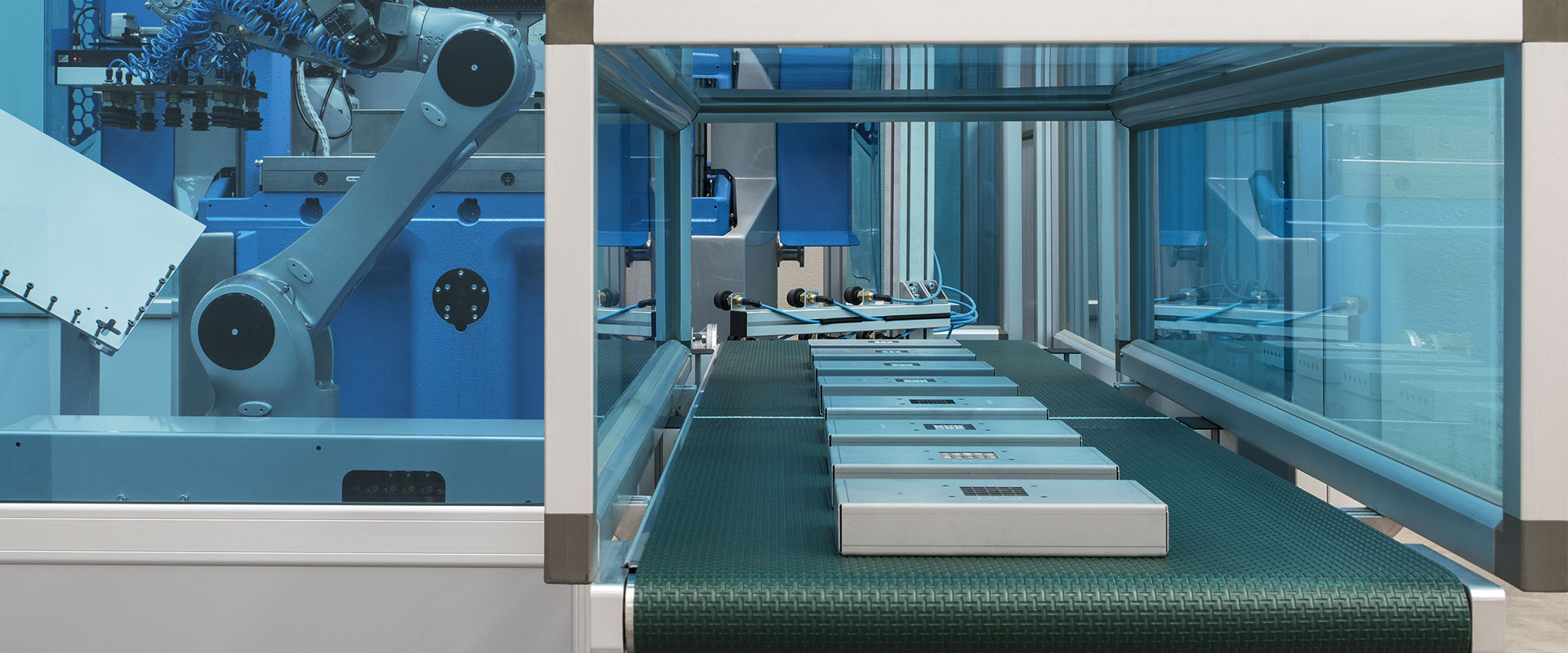

The cell is integrated by:

• Fx Bend with 6-axes backgauge

• Robot Kuka KR10 cybertech nano

• Base of the robot integrated into the machine

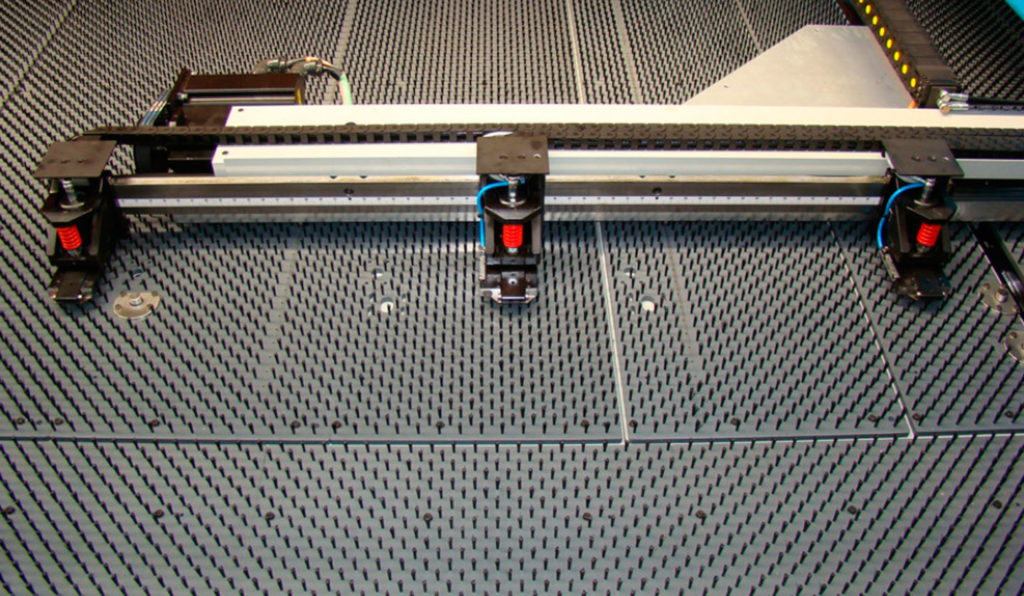

• Turnover system

• Double part control

• Loading station with 2 tables of 1200 x 800 mm

Unloading:

• Palletization on a Europallet

• Automatic belt conveyer for unloading into a box (optional).

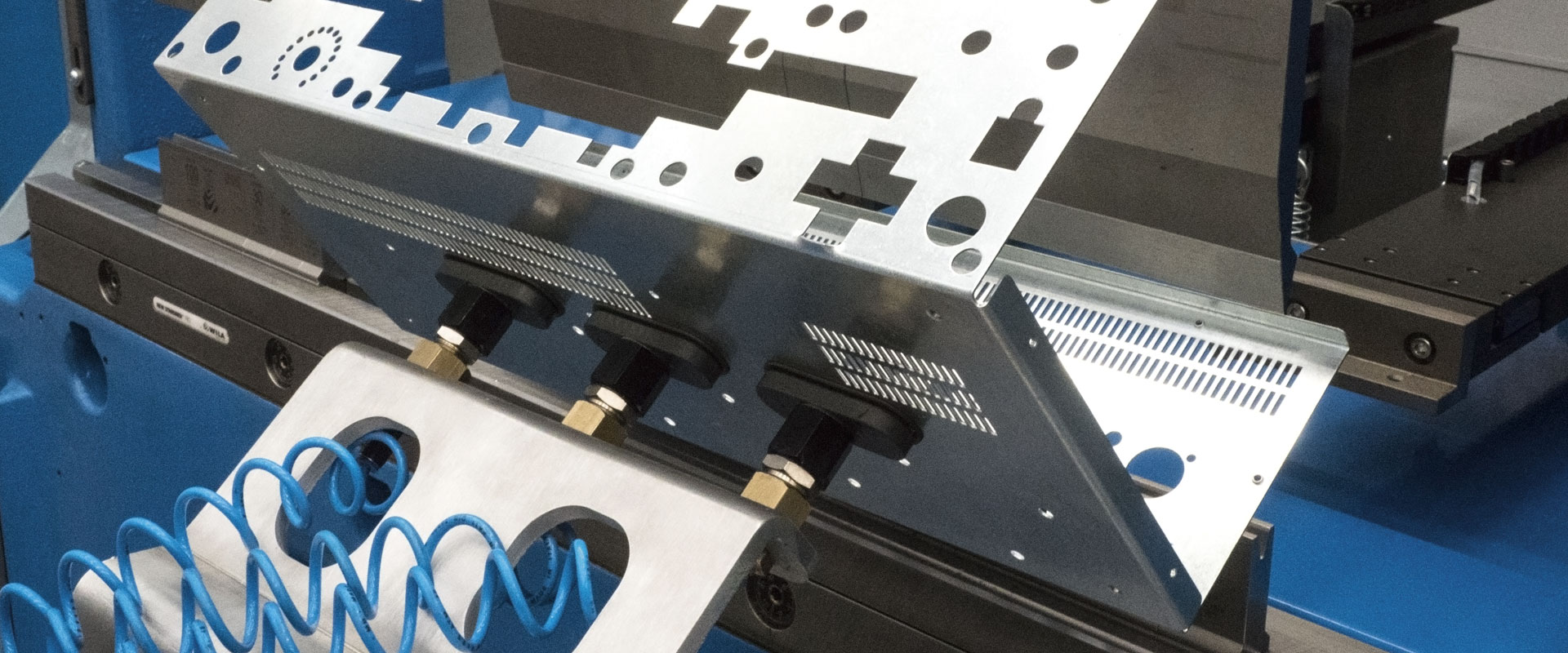

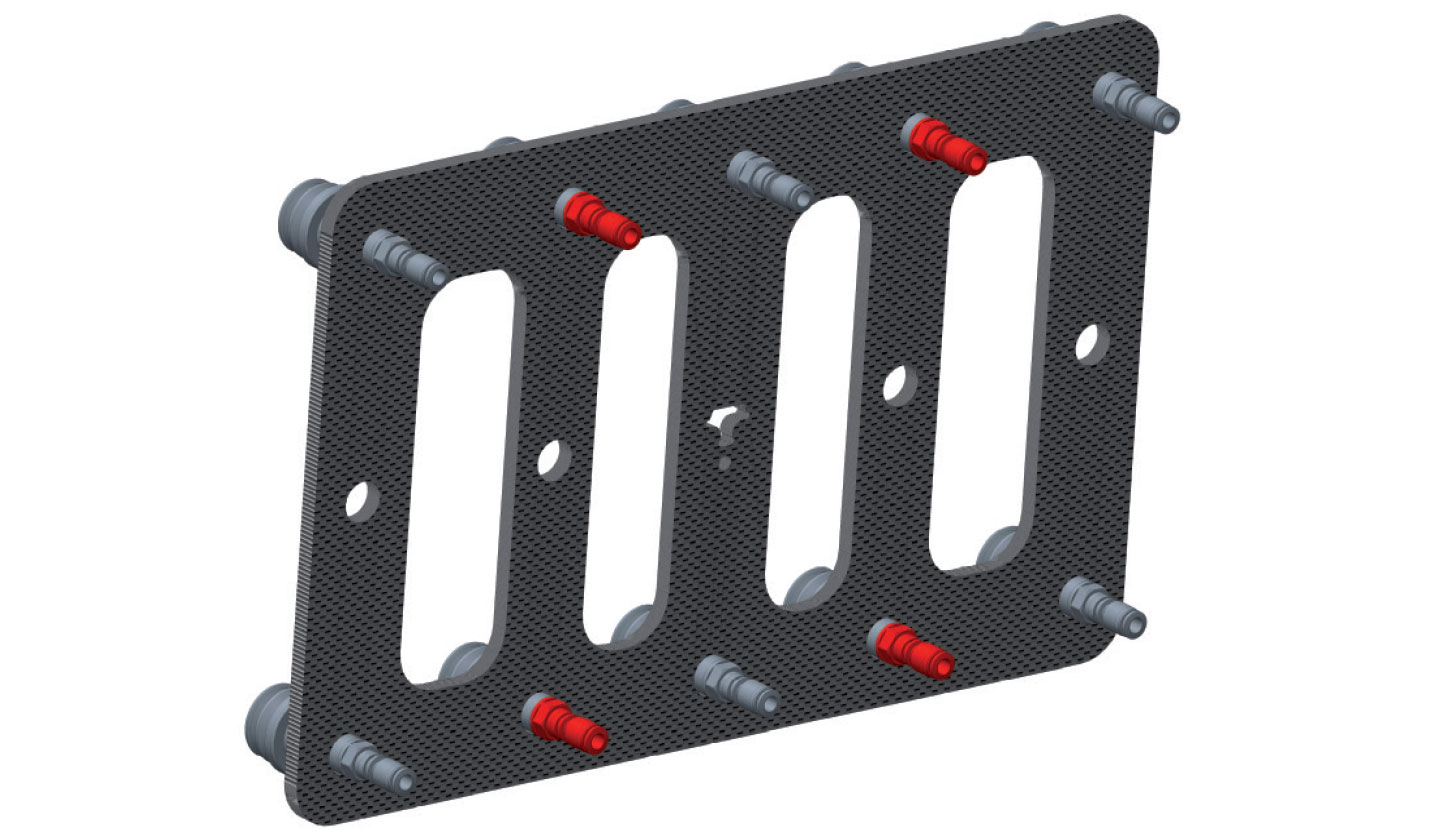

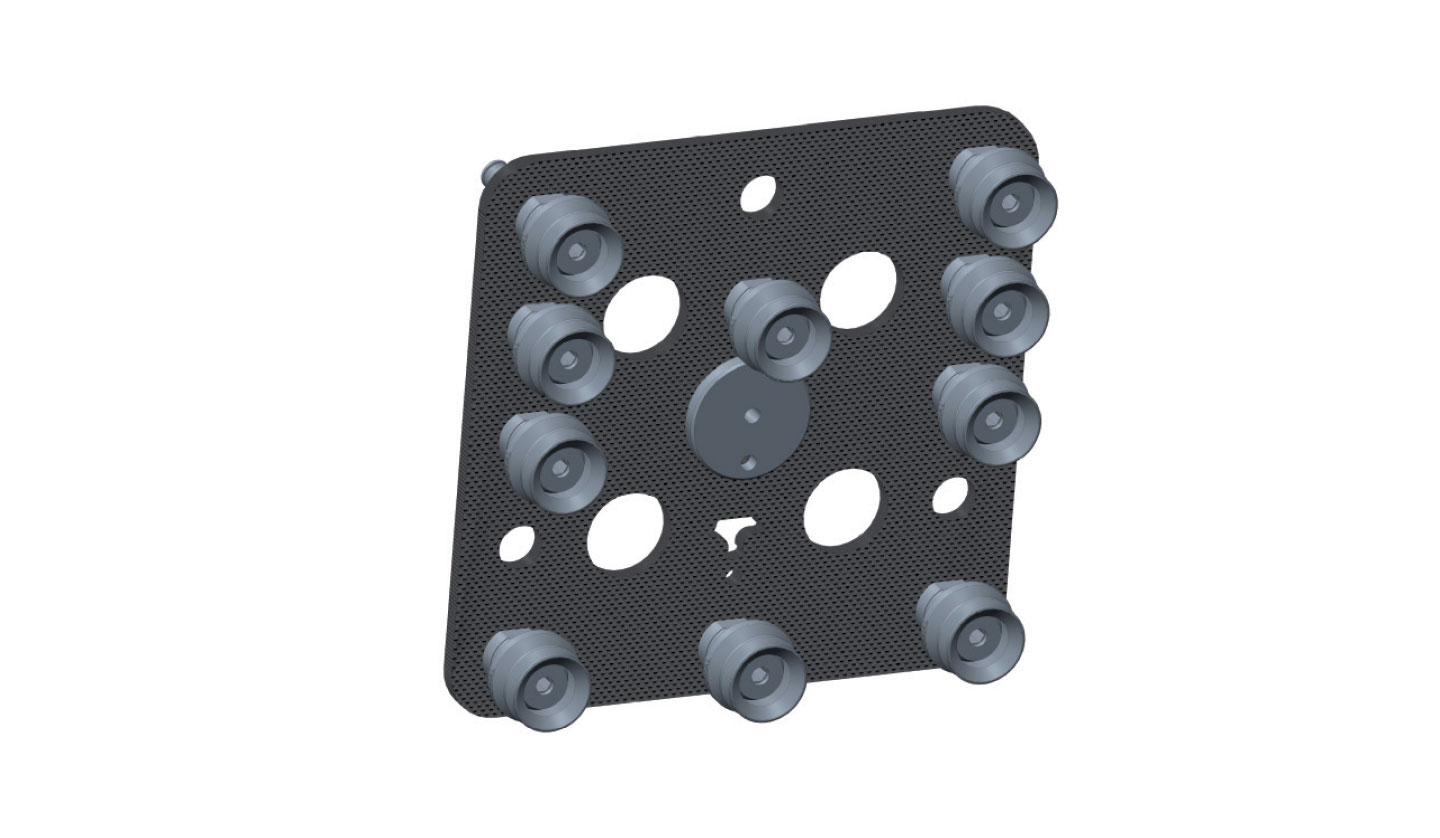

Tools

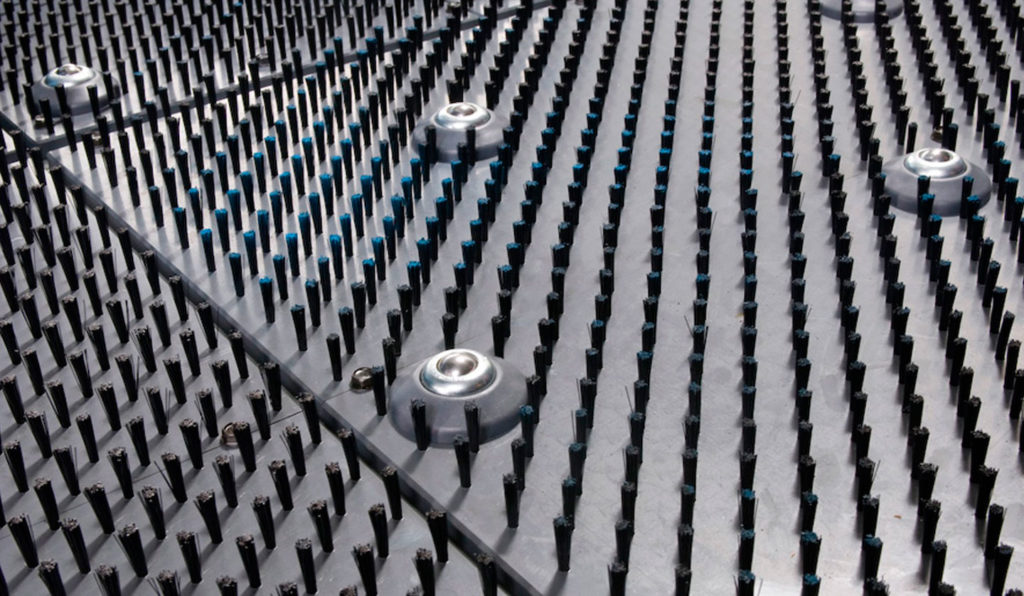

Gripper with vacuum for medium format parts

External dimension 230×230 with the possibility to insert up to 10 suction cups.

Video

Optionals