Does the impossible exist? The endless possibilities of automated press brakes

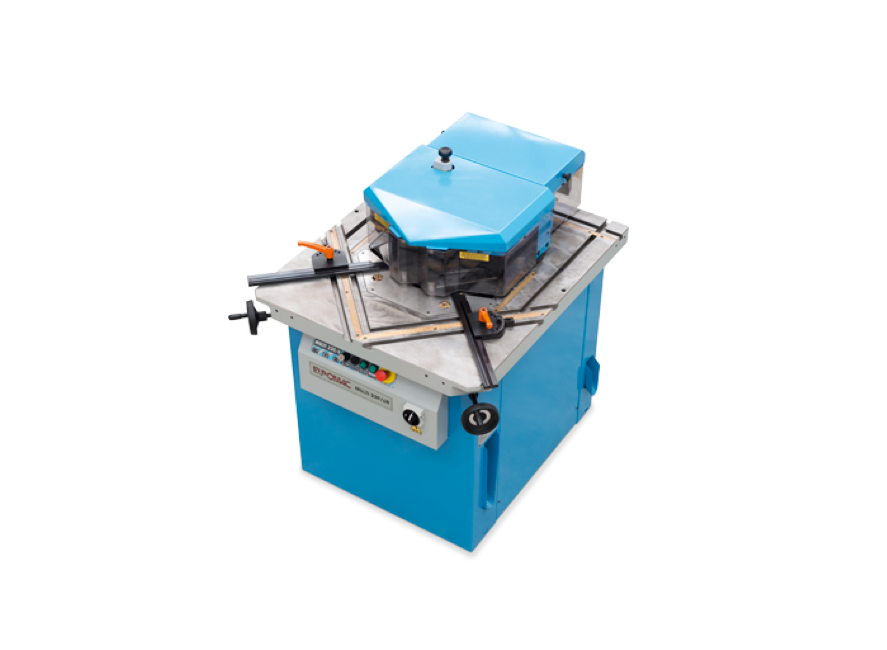

A bending process is definitely not an easy job. Some even say it is an art.

Demand is increasing, as is the complexity of work pieces and – consequently – the possibility of committing errors.

Finding specialised personnel is now starting to become a challenge.

It is necessary to find a solution that significantly increases productivity while optimising costs. To perform increasingly complex and precise bending processes, while, at the same time, reducing the margin of error. To be able to work for increasingly longer periods of time, without interruption.

When robotics meet bending processes

A solution to this exists.

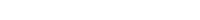

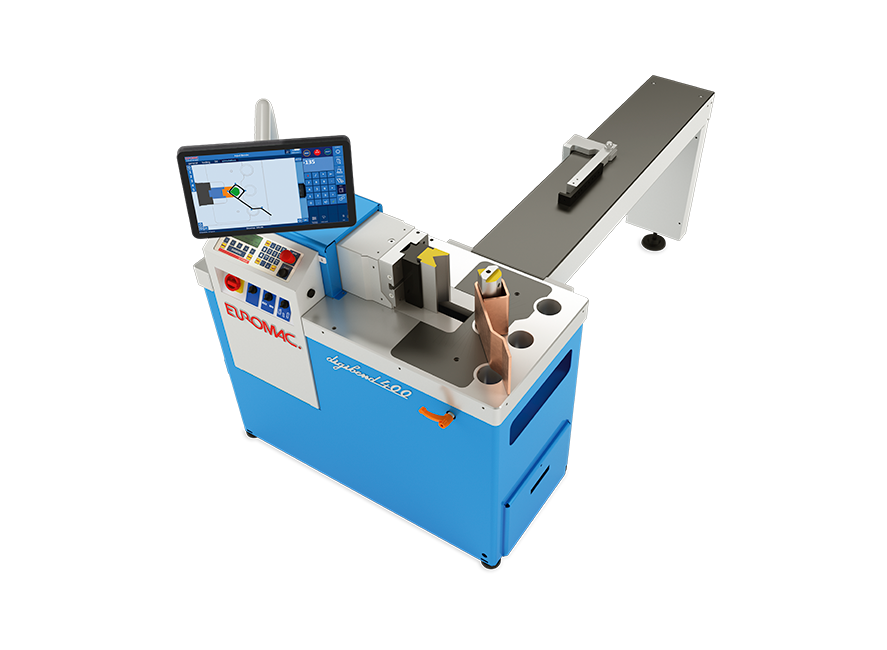

The automated press brake.

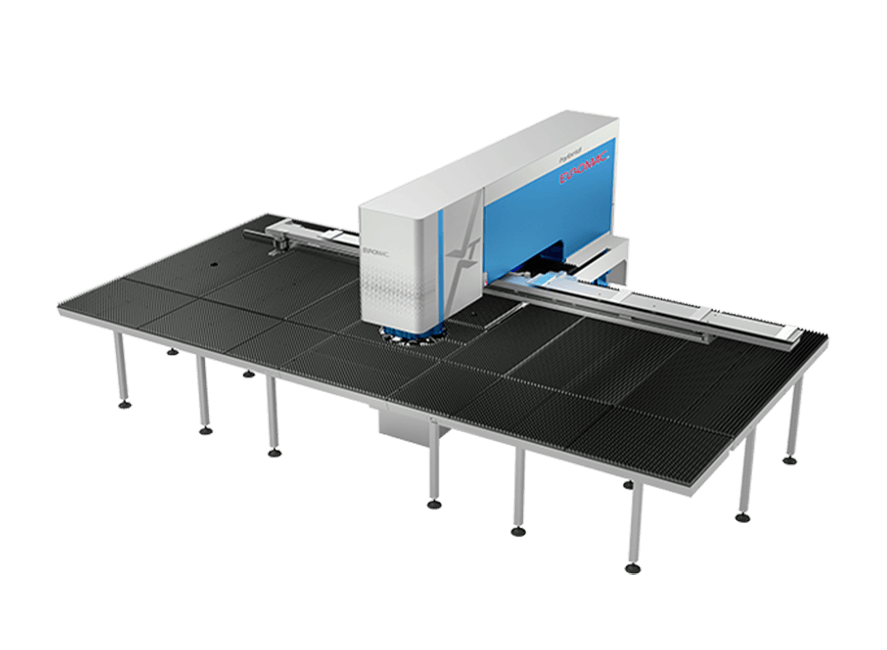

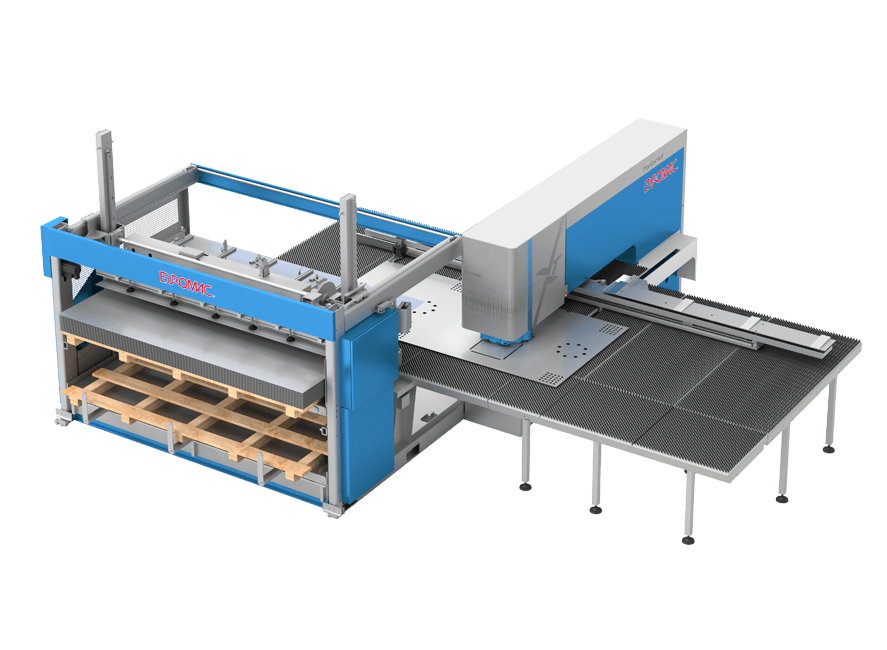

Thanks to robotics, a single press brake can now perform tasks autonomously that used to require three or four different machines.

Steps that were previously carried out by human hands are now entrusted to robotic arms capable of achieving new levels of precision.

The automatic systems are able to continuously feed the press brakes, new workpieces are processed non-stop.

The work of the technicians remains indispensable, they are responsible for supervising and programming the machine.

Complexity made simple

One might think that the complexity has simply been shifted from the operational side to the programming side.

Indeed, it has.

Unless your press brake is fitted with state-of-the-art software.

Software designed to be easy to learn and, above all, to use.

The software that we, at Euromac, have developed for automated press brakes is designed to meet these requirements. It is so easy to use that training can also be carried out remotely.

It is impossible to know what the world of bending processes will look like in twenty years’ time, but if you would like to take a peek into the future, then click here.