Euromac participates in BlechExpo 2023

The BlechExpo trade fair is the event where sheet metal working companies exhibit their most innovative machines.

Euromac focuses on innovation, and this year we will bring a selection of machines that, in addition to efficiency and reliability, are especially

Energy efficient

In recent years, energy cost increases have had a major impact on sheet metal companies.

It has made us realise how vital energy is to our margins and business.

Now the costs have come down, but we will never see the same prices we had three years ago, so energy saving and efficiency have become essential keywords for any new sheet metal working solution.

Euromac is ready.

A history of innovation with a focus on energy saving

At stand 1408, Hall 1, our technicians will unveil the energy-efficient solutions we have developed over the decades.

We say decades because efficiency, including energy, has been part of our mission since the beginning.

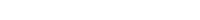

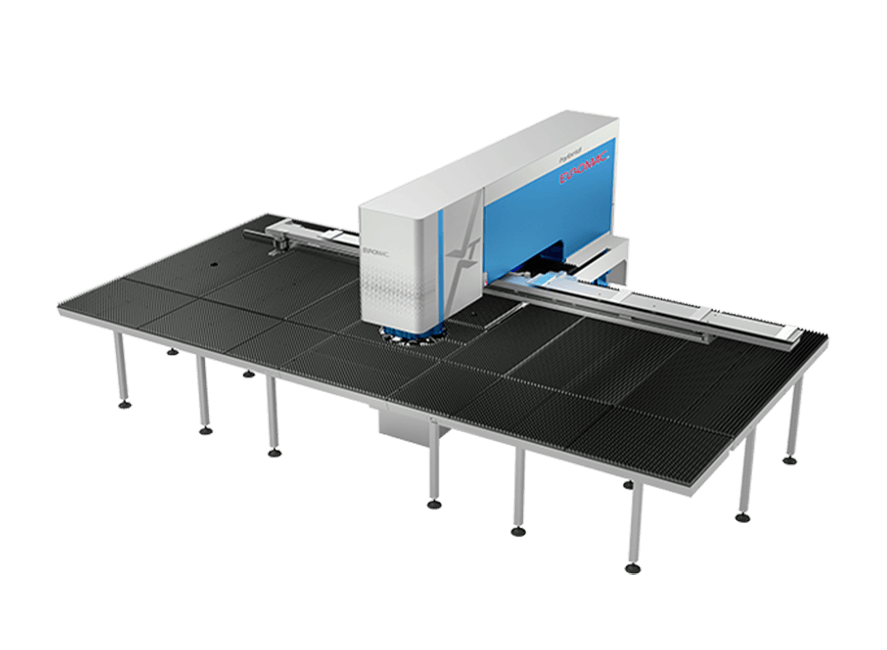

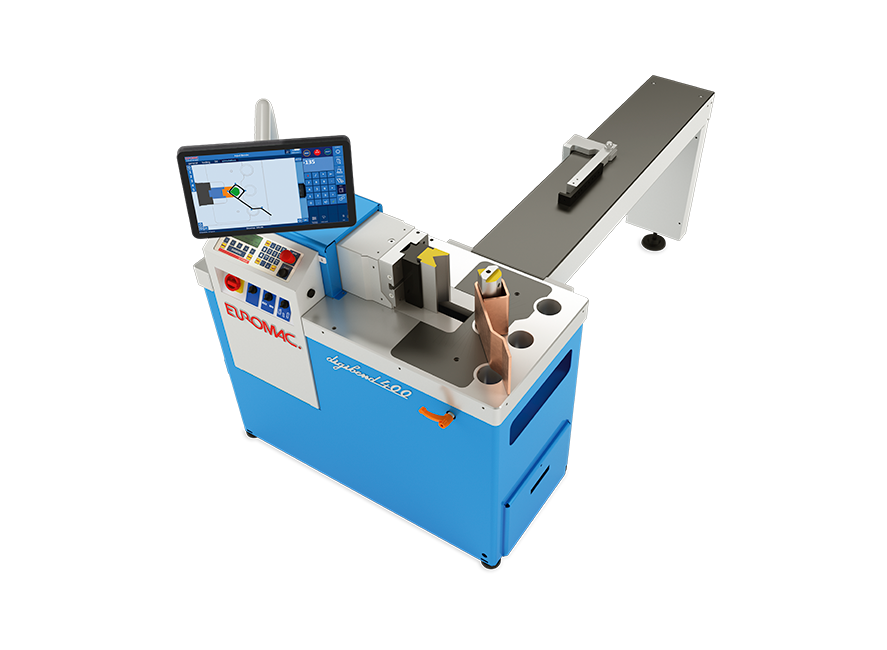

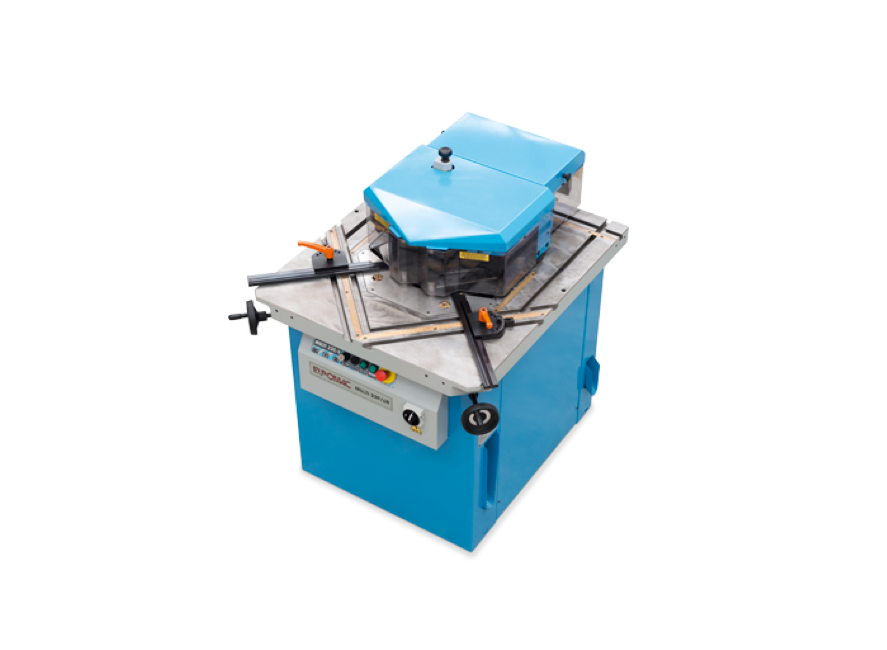

It is the quest for energy efficiency that has led us to develop electric punching machines instead of getting into laser machines, such as the XT electric punching machine. With its loading/unloading station, the XT ensures an average energy consumption of 2.5 kW. A classic Euromac production, the Digibend 400 horizontal bending machine, has an average energy consumption of 0.9 kW.

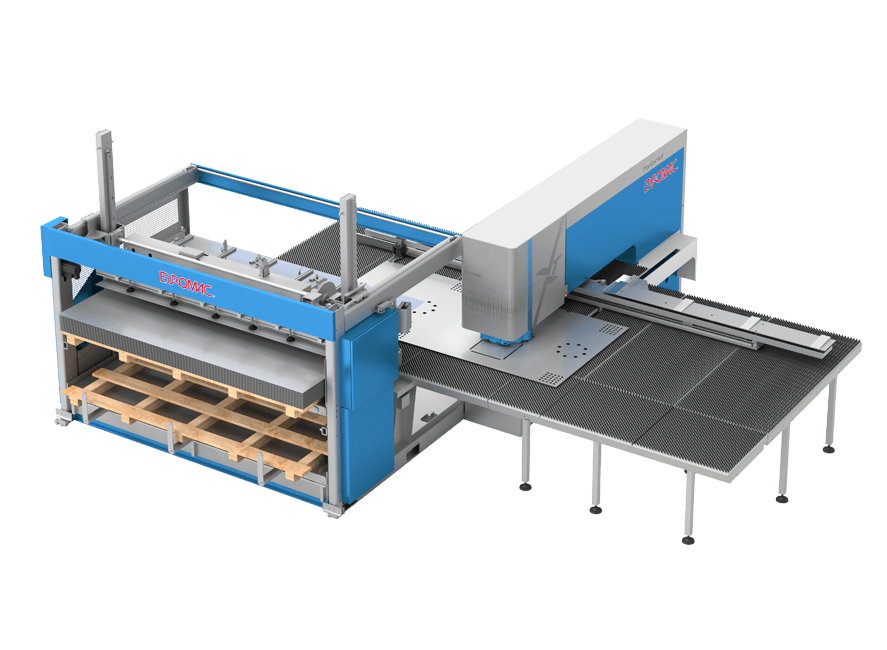

The quest for energy efficiency has driven us to adopt automation so that our customers can move to night-time production, when costs are lower. The Fx Bend press brake equipped with a robot, provides an average energy consumption of 1.8 kW. Thisencouraged us to develop increasingly effective software for production optimisation.

Take a closer look at the Euromac machines and software and find the most suitable solution for your business.

See you at the trade fair, stand 1408 – hall 1.