The paradigm is about to change: discover the new CPX for full copper cycle

Ongoing evolution is part of Euromac’s DNA. Hence, having set a standard, we stay focused on improving, without ever stopping.

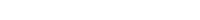

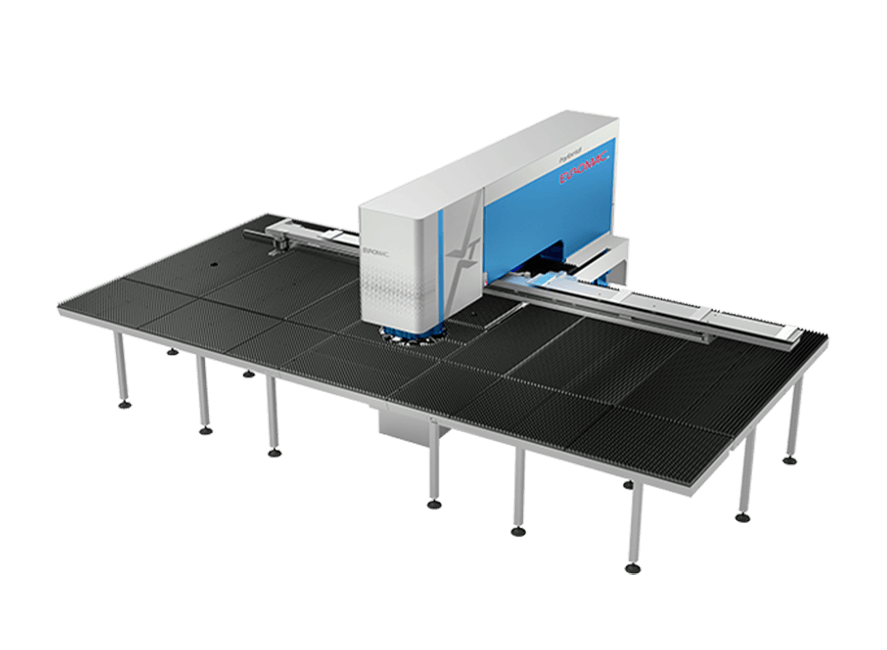

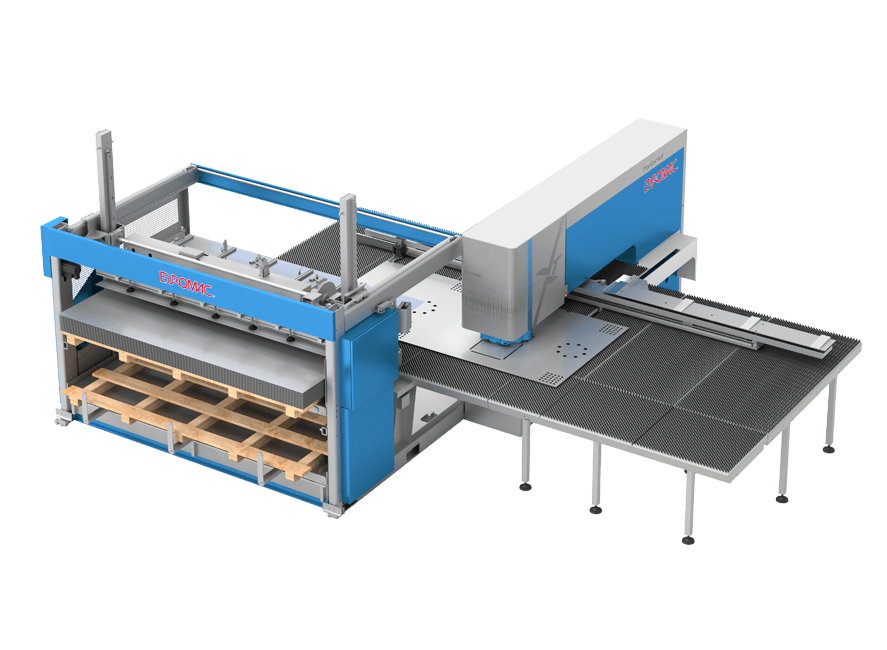

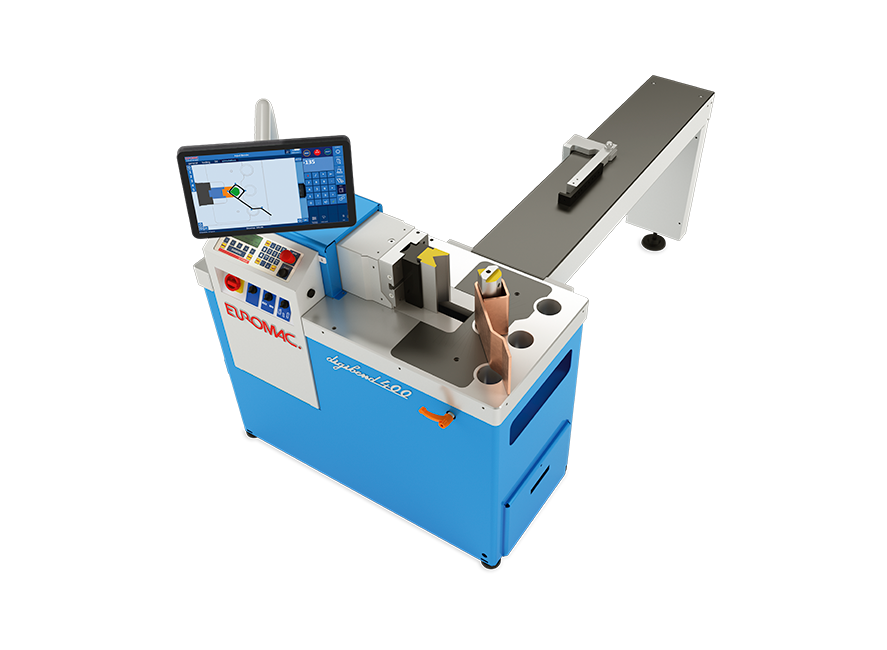

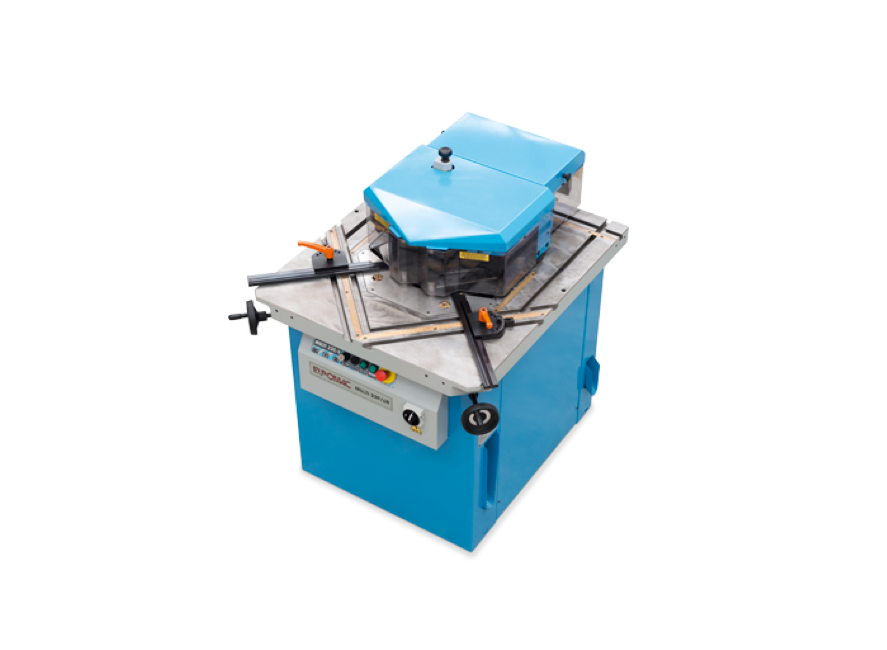

The new CPX punches and cuts copper bars, preparing the material for further processing, for example with our Digibend bending machine.

This is a major technological change: Euromac completes the copper processing cycle for the first time. The new CPX machine punches and cuts, while Digibend folds and punches.

More parts, less time: today it is possible with the new CPX

A state-of-the-art solution that aims at improving the productivity of those who have to produce large quantities of parts.

All this is possible with the highly advanced technology of the latest CPX, the outcome of Euromac’s almost 40 years of experience and in-depth knowledge of the industry, evidenced by highly successful longsellers, such as the Digibend bending machine.

Furthermore, the partnership with the Finnish company Vaski has further enhanced project quality. The result is a solution that changes the paradigms of copper processing.

High speeds and high productivity that do not affect the traditional precision of Euromac machines.

Moreover, the new CPX is cost-effective as it optimises consumption, while reducing both time and costs.

How does it achieve this?

Outstanding performance and resource optimisation

The new CPX from Euromac is designed for the automated copper processing production process. This means greater speed and productivity.

Moreover, being electric, the new CPX allows significant energy savings of up to 90 per cent. With long-standing experience in the industry, Euromac guarantees an average 50% reduction in maintenance time and costs with CPX.

New CPX: an all-in-one with countless advantages

Just launched, the new CPX is bound to have an impact on the industry.

Investing in the new CPX means investing in one’s own productivity, limiting consumption and safeguarding profit margins. Let’s look into the future

Follow us to find out when it will be available, and to learn about future Euromac innovations in copper and sheet metal processing.