Proud to make a difference! The success story for DM Inox and Euromac

At Euromac, striving for the best lies at the heart of our corporate culture, and continuous improvement is our modus operandi. But when can we really be sure that we have achieved our results?

When the customer tells us so!

⚙The customer

DM Inox is a well-established sheet metal working company. As a reliable supplier for third parties, it performs laser cutting, welding, bending and finishing on stainless steel, iron and aluminium. It produces components for industrial machines and fairings, shells and structural elements for OEM manufacturers, as well as elements for professional catering, for kitchen countertops, ovens and refrigeration systems.

DM Inox carries out custom processing for special projects, and can supply single components, complex assemblies and complete batches.

⚙The challenge? To increase productivity.

DM Inox is used to working within a constant situation of flux and integrating new technologies comes naturally to it.

In 2022, the company found it necessary to increase the number of machines to further improve production capacity.

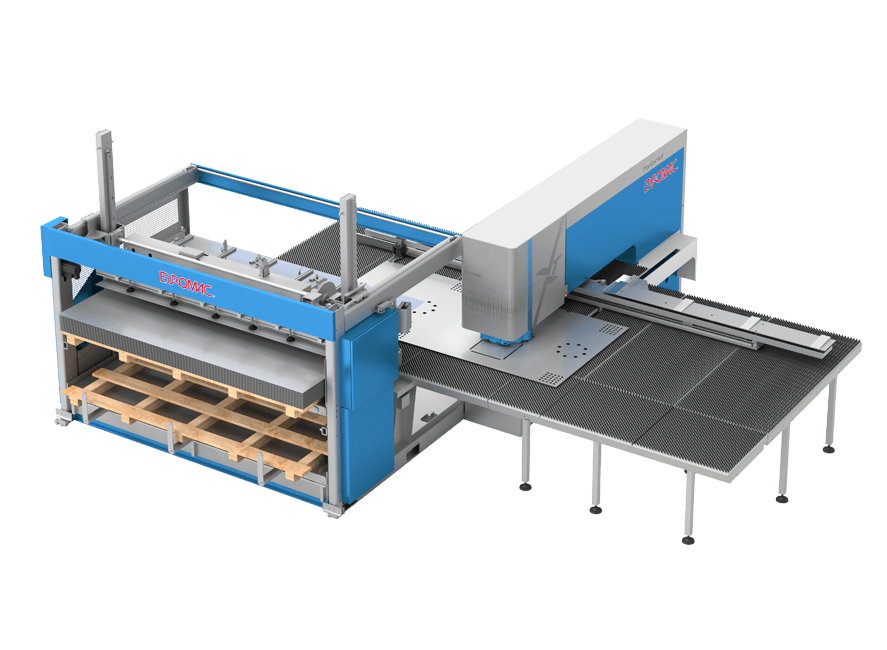

A new cell was needed to produce high rotating parts to relieve operators of repetitive tasks and set them other targets where humans still make a difference.

⚙The solution? Euromac.

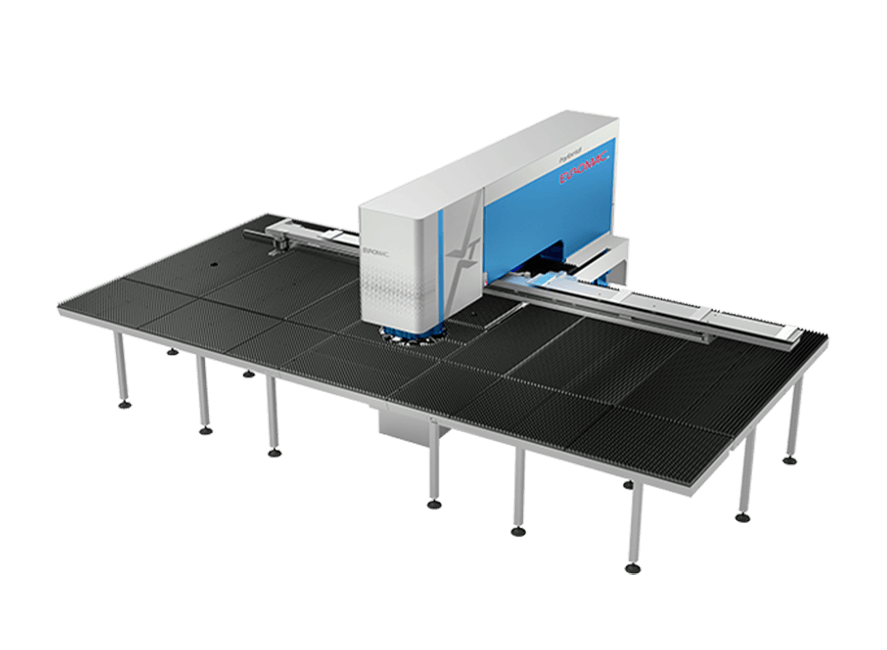

After many months of study and after evaluating 5 different suppliers, Euromac set itself apart by proposing a turnkey solution that guaranteed DM Inox continuity with an existing plant: using the same online software and the same robot.

Euromac also guaranteed commissioning within months, strongly supporting DM Inox in its change of production scenario.

⚙The positive impact of Euromac

Euromac adapted the elements of its standard solution, starting from the conditions set by the existing plant. It immediately honed in on the right solution, following an approach that focused on the real needs of the customer.

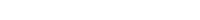

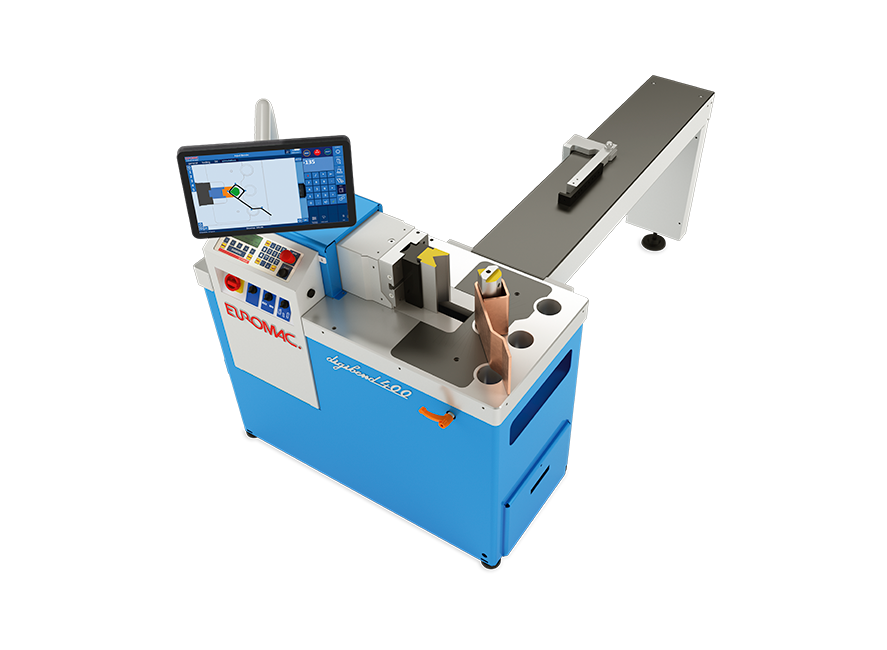

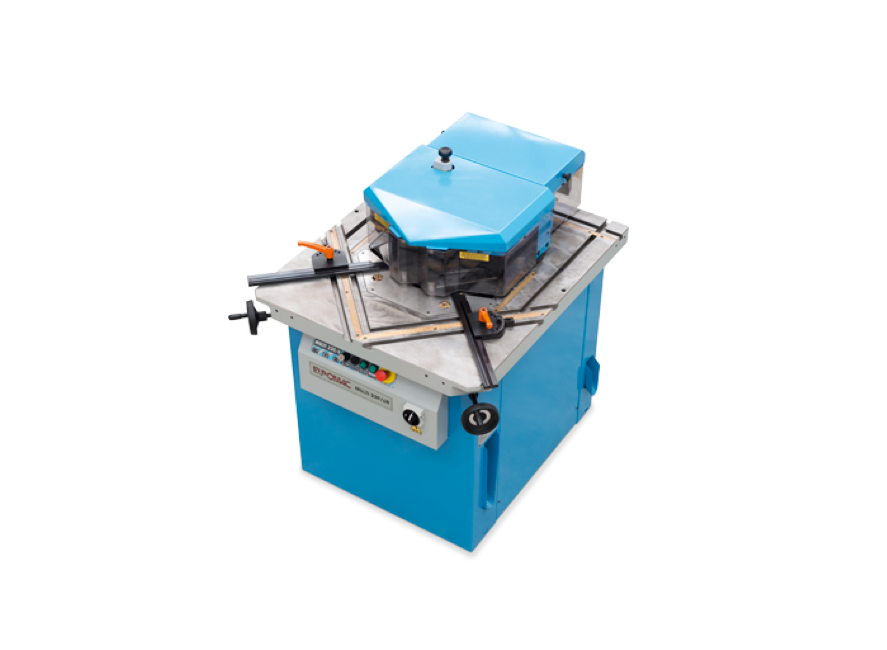

The cell supplied by Euromac is flexible and can be adapted to new production needs. It offers everything needed: a compact functional robot press chamber, which simplifies the set-up of new cycles, and high loading and unloading capacity.

With the addition of care and constant support both in development and after sale and responsive and timely technical support and assistance, the end result could only be called a success story.

To learn more about Euromac’s solutions for DM Inox, watch the video.

If you are looking for someone to design the right solution for your new operational needs, do not hesitate to contact us! #ProudToMakeADifference

Title: DM Inox chooses Euromac to write a success story

Description: DM Inox, based in Sospirolo (BL), changes its production scenario with Euromac’s turnkey solutions.