Punching machines vs. lasers: an astonishing result

Laser: a word that easily recalls associations with ‘innovation’, ‘advanced’, ‘future’. When it comes to sheet metal working, however, the issue is more complex.

Let’s make an objective analysis. On what do we base the efficiency of a machine?

Quality/price ratio

Given the greater complexity, the cost of a laser is considerably higher than that of a punching machine.

The winner is: the punching machine.

Hourly rate

Lasers require gas and much more energy to operate than a punching machine. Due to their greater complexity, they also require very frequent maintenance.

The winner is: the punching machine.

Precision

Contrary to expectations, the precision of lasers and punching machines are remarkably similar. Indeed, the laser also needs to manage the burning of the first hole, often to the detriment of machining times.

The comparison results in: A draw.

Flexibility

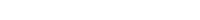

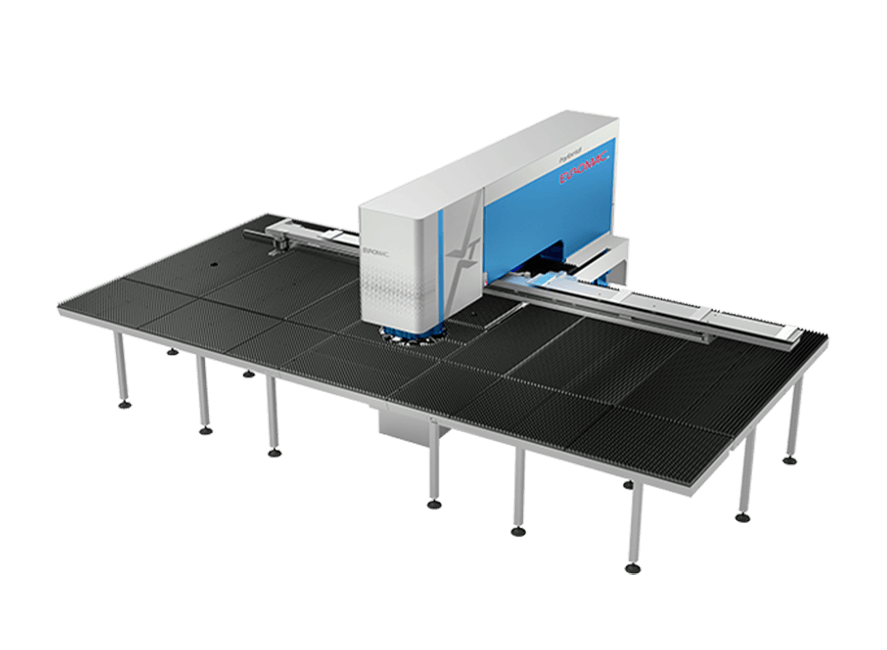

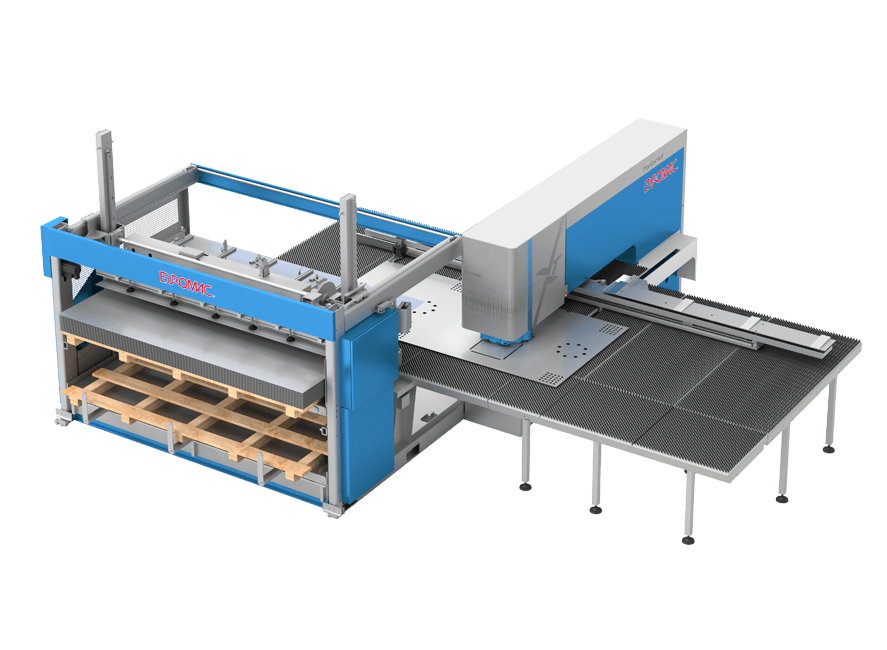

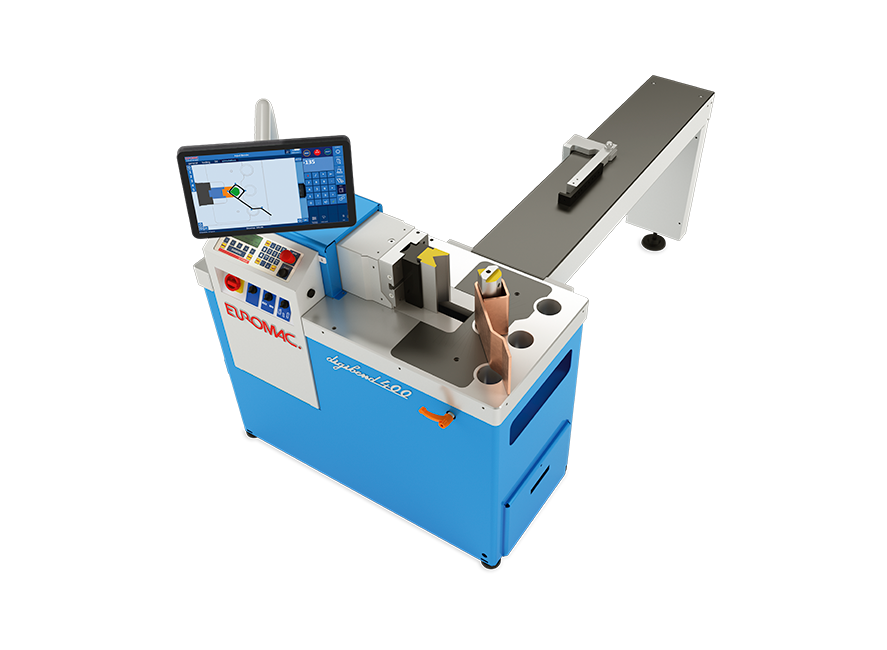

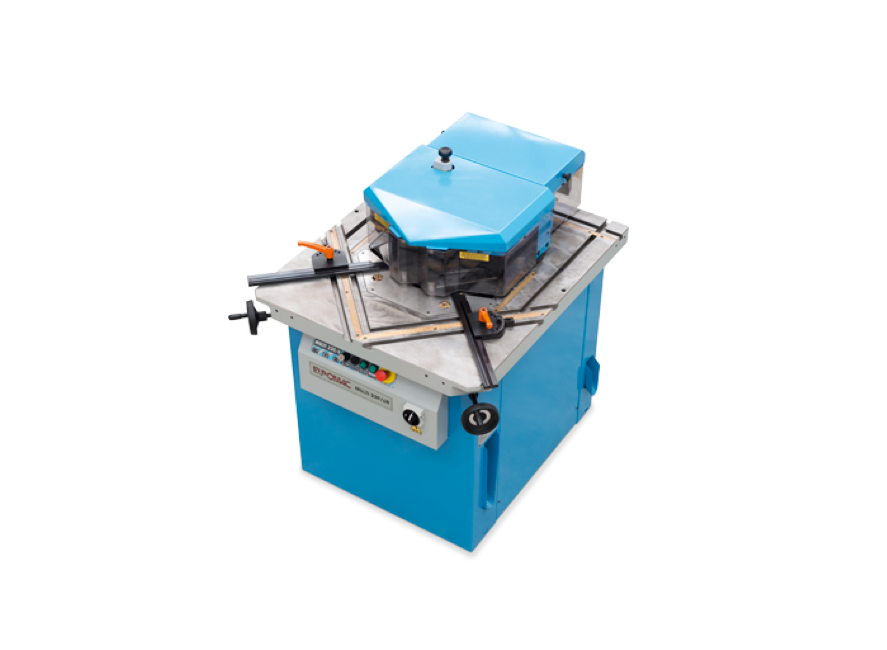

A laser drills or cuts. A Euromac punching machine can also perform ribbing, bending, threading, forming, edging and marking.

The winner is: The punching machine.

Will lasers be the future of sheet metal working? Perhaps.

TODAY, however, the punching machine is the best possible choice.

If you would like further information on Euromac punching machines, contact us!